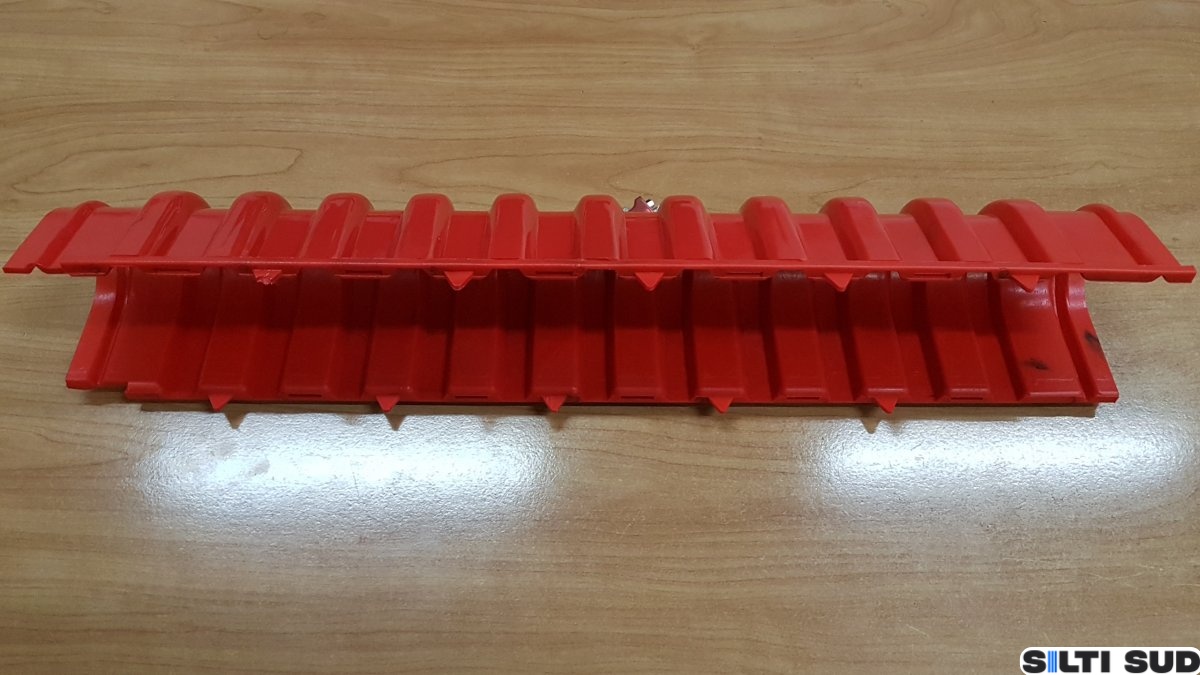

Cover duct for underground cables

Use:

It is used to cover underground cables: electrical, telephone, fiber optic, or similar, protecting them from crushing and accidental impacts.

Material:

Hot-molded thermoplastic.

Characteristics:

The conduit is lined with a series of protrusions and recesses along its curved section, spacing out the entire profile to stiffen the covering.

It can be interlocked with other conduits in succession via an overlapping edge, as shown in the figure.

On the edges where it rests on the ground, the conduit is equipped with a series of downward-facing prongs to prevent movement and deformation when subjected to crushing or impact under load.

Thanks to its light weight, it is not only much easier to handle than commonly used concrete and fired conduits, but it also completely eliminates the risk of breakage that normally occurs in the event of a fall or during installation operations.

Performance:

Crushing test: The test was performed by subjecting the cable duct to a distributed load of 1000 kg for 20 minutes, as per the UNI 4095 standard for concrete products for buried cables. After 20 minutes, the cable duct was found to be in perfect condition.

Percussion tests: Repeated percussion tests were performed with a 10 kg rod ending in a cemented spherical tip, as per the UNI 4095 standard, and dropped from a height of 50 cm without damage.

Breaking test: 1000 kg/m.

Resistance to aggressive agents possibly present in the soil and with a temperature range of -20° to +60°C.

Dimensions: 500 mm in length for each individual module.

Maximum usable height = 75 mm – Maximum usable width = 75 mm – Thickness = 3 mm.

Colors: Customer’s choice.

Weight: 450 gr.